Kitchen / Dining Room Blog, Cutting Boards Blog, Workshop Blog

Why do end grain boards crack?

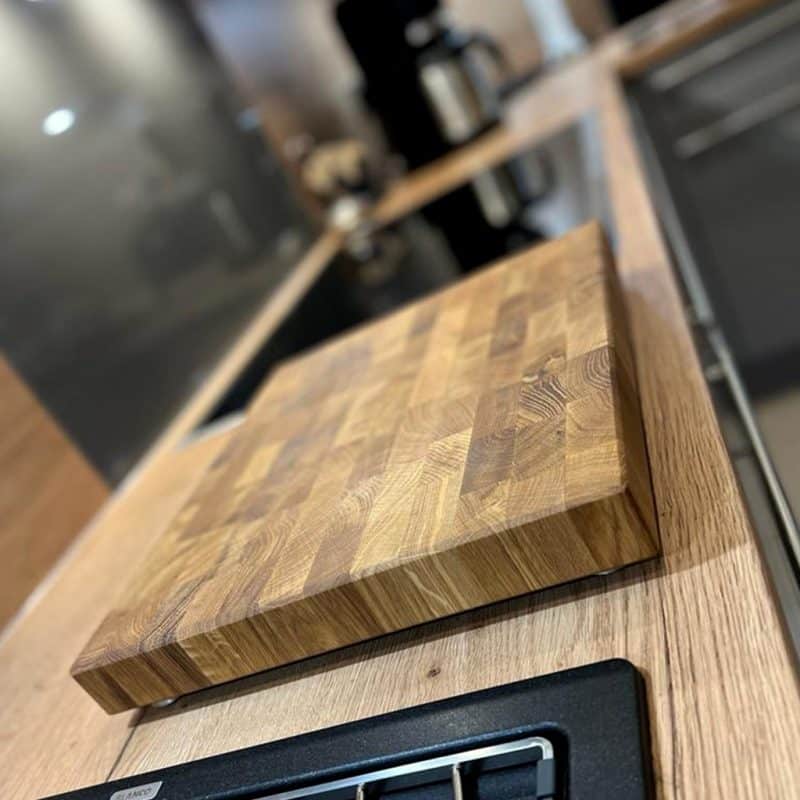

What is end grain wood?

The terms end grain or cross grain describe the same type of wood processing. To produce them, wood is not cut lengthways to the trunk as usual, but across the trunk and then glued together again. This means that you look at the tree's annual rings from above. The end grain surface has many advantages and special features. We would like to discuss some of them in this article and, above all, explain what the biggest mistakes are that cause a board to break.

Why a cutting board made of end grain wood?

End grain and cross grain are suitable for the production of Cutting boards very good. The visible grain of the annual rings creates a very attractive pattern. This wood also offers a number of advantages. In this type of production, cuts are made in the wood in such a way that the fibers split and do not cut. The wood fibers swell when exposed to moisture (wipe over with a cloth) and close fine cuts again, so that the Cutting board looks like new for much longer. This does not destroy the wood fiber, but simply separates it.

Chopping blocks are often made from end grain wood. The position of the fibers means that the pressure from the heavy chopping knives is distributed better and the blade's deep penetration into the wood does not damage it as much as with conventional cutting boards. In the past, this was found in every village butcher's shop, but today it can be seen in many domestic kitchens.

The right type of wood is important

If end grain cutting boards have so many advantages, why are they tearing them down?

First of all, I would like to warn you against buying your end grain board without thinking it through from the nearest dealer – the internet offers many options for getting good cutting boards but also really bad ones. A huge number of dealers, whether online or stationary, sell end grain cutting boards made from beech, rubber tree or maple. The first two mentioned in particular are significantly cheaper than, for example, German oak. But that's not all. They are simply not suitable for end grain cutting.Cutting board-Processing. The properties of beech in particular speak against this type of processing. Too much moisture on the board and the next day the first crack appears. The dealer usually ducks away and says that it was not handled correctly. Therefore, my most urgent advice is to look at what type of wood is being used and find out more before you buy. oak, cherry, Ash, nut, birch, Apple, larch,… these are all types of wood that are ideal for end grain boards. Manufacturers like us do not only pay attention to an aesthetically pleasing board, but above all to its function. This requires wood expertise and craftsmanship as well as the necessary machinery. When everything comes together, great end grain boards are created. We ourselves have the beech and the maple Although listed as an article, it is not unlocked for purchase.

The right type of wood is important

If these high-quality Cutting boards If the board still tears, it can have its origin in the processing or in the handling of the wooden board. Basically, it must not be forgotten that this type of production is not intended by nature. Wood wants and will also be used in the form of a Cutting board work. Especially when it gets wet and dries again. With an end grain board, the small cubes are surrounded by other cubes and are literally locked in. The result is that the wood cannot work as it would like and begins to crack. Active wood care is therefore essential.

Manufacturing errors

Many mistakes can happen when making the end grain board.

An important step is gluing the individual end grain pieces together to form a board. If too little glue is used, or too little pressure is applied when gluing, the connection is not stable enough and tension in the wood can lead to cracks. Too much residual moisture in the wood will also cause the board to split.

Errors in use

Even if everything was done correctly during processing, you can still make a number of mistakes when handling end grain wood in everyday life. If you follow the following points, your board should look good for a long time and give you lots of fun while cooking:

Make sure that the board is not permanently exposed to strong sunlight or other heat sources. Wood is a natural product and reacts to heat. And also to large temperature fluctuations. A hot pot is also a no-go. The black burnt spots are not caused by end grain. Cutting board earned.

Once you have cleaned your cutting board, it should be dried thoroughly while standing up. Waterlogging damages the end grain, as does cleaning for too long with too much water. Foods with a high water content, such as tomatoes, should also be processed quickly and the tomato juice dried or removed from the board. The dishwasher is also the ultimate punishment for end grain boards :-). If possible, do not drop the board, as impact creates too much pressure at one point, which can also cause cracks or at least an unsightly dent.

Treat your end grain board to a little oil at regular intervals. The wood oil creates a protective layer in the wood and on the surface so that not too much water penetrates the board. We can use the oil we use Linseed oil varnish highly recommend. Of course the oil is food safe and 100% organic.

The dishwasher is the absolute ultimate punishment for the end grain board 🙂

Hello Mr. Hekler,

I have been using your XXL oak wood chopping board for about 2 months now. It is placed on a non-slip mat and is regularly treated with walnut oil on both sides every 1-2 weeks. The board is absolutely flat even though we only use one side at a time. No tipping, no warping. Although the breathability on the underside is not as good as on the top - it should work like this in the long term. Or what do you think?

PS. Your website, your personality and your comments seem very authentic and personable. Anyone who buys wooden boards from anywhere else today has only themselves to blame and should gain experience with cheap quality.

Best regards,

Thomas Goerne